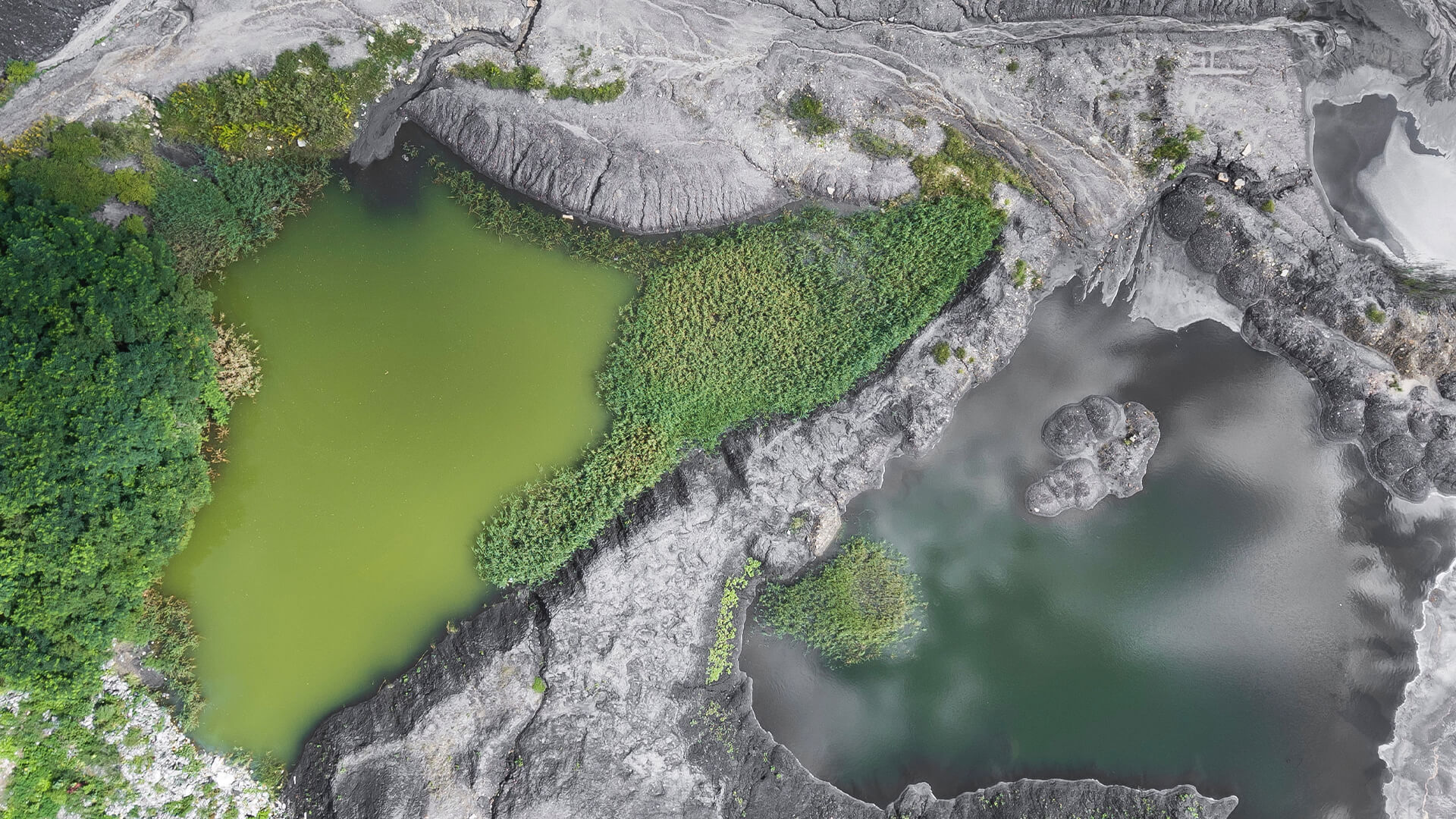

Mining

3D digital reconstruction using proven drone technology provides major improvement in resource & hazard identification, increasing efficiency and safety of the sites at a low cost.

Overview

A mining client was seeking to implement UAS into daily operations to assist mine planning and production engineering. Their desire was to acquire more precise volumes of ore and waste material mined. They also wanted to provide a safer method to acquire shovel production data. Aerial data collection could offer a way to gain accurate volumetrics while maintaining safe and remote distances from the area of mining operations. Drone pilots were required to have MSHA Part 46 knowledge and certification. In addition, Pilots also were required to attend site specific induction training.

Method

Flights were scheduled daily as a result of a shovel production report. This would reflect each shovels activity within the last 24hr period. The Pilot would examine previous 3D models of each active area to determine the best opportunity for safe flight and full coverage for effective data acquisition. A full data set of each shovel location could be acquired in its entirety within about 5 to 10 minutes of flight time and 15 to 20 minutes of pre-flight setup and procedure. Optimal flight path, camera angles, and flight speeds were determined through the flight systems controller software. The Pilot uses a drone that has RTK GPS capabilities, which eliminates the need to set and survey ground control points, avoiding exposure to hazardous/active mining areas. In addition, the flight controller software sourced previous 3D model data to interpret the unique terrain features of each area of the mine. In conjunction with the “terrain follow” features, collision avoidance sensors onboard the drone could ensure that redundant safety measures were in place. Flight patterns for each shovel pit location are loaded into the flight controller database, which ensured a safe and effective flight for each area of the mine.

Data Deliverables

Utilizing the photo data collection, the Drone Pilot was able to upload data to a commercial grade geomatic database. From there, desired deliverables could be generated. The typical daily data deliverables would include the following:

- High-resolution 2D orthomosaic maps

- Volumetric reports, as requested for individual Shovel locations

- 3D digital terrain modeling and topographical map generation

- Shovel pit and cut/zone progression overlays and animations

Result

By producing a daily digital report of shovel pit progression, the mine planning department was able to quickly analyze and verify material processed for the last 24hr haulage period. Through comprehensive digital documentation, the client had on-demand access to key insights. With various data deliverables available, decisions were quickly coordinated and clearly made to modify mining activity and optimize ore production and waste material disposal. Increased productivity and ROI were realized through better time management, more precise measurements of material processed, greater insight to shovel operator performance, and overall scrutiny of mining plan execution. Ultimately, higher quality data was being acquired in far more safe circumstances and at a more efficient rate of delivery.

Get Your Project Off the Ground Today

We have highly talented pilots all over the United States & beyond on the ground waiting to fly just for you. With this depth of qualified people, there is no job (or flight path) we won’t take.